Pye Group is an agricultural company owned by Leighton and Michelle Pye, operating 11 dairy farms and over 4,800 hectares of land across Temuka, Rangitata, Hinds, Rakaia, and Fairlie.

Their primary activities include dairy grazing for their own cows, substantial cropping (grains, wheat, barley, milling wheat, specialty grasses, and vegetables), and supplying turf grass to the US for golf courses. They also supply 25,000 tonnes of carrots and 15,000–18,000 tonnes of potatoes to McCains annually.

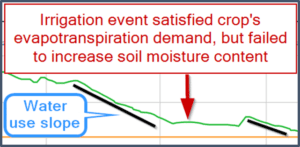

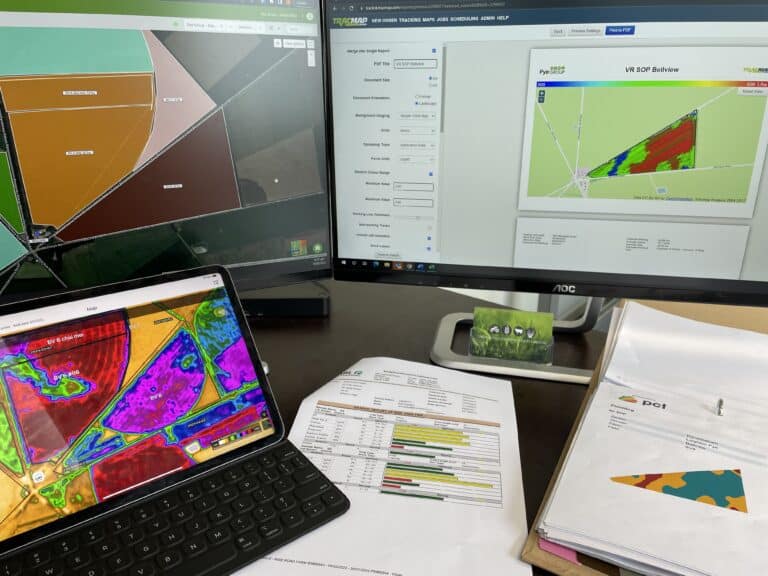

Working with Vantage NZ since 2012, the company has invested in soil testing, moisture probes, EM soil surveying, and yield mapping. This has helped them better understand soil quality and exactly what nutrients each piece of their land needs.

One of the biggest challenges for Pye Group is ensuring a balanced nutrient supply for optimal growth on their cropping farms and being able to provide proof of placement. Prior to working with Vantage, the group used blanket application of fertiliser, applying a standardised amount across the whole farm.

The solution:

With Precision Nutrient Management, they are now able to apply variable rates of products such as Lime, Potassium Chloride, Superphosphate and Magnesium Oxide based on maps that outline the exact quantity each part of the paddock needs. They have found that in some paddocks, three quarters will receive no nutrients, and one corner will need four different rates. If they had blanket applied, they would have overloaded the majority of the soil.

Outcomes:

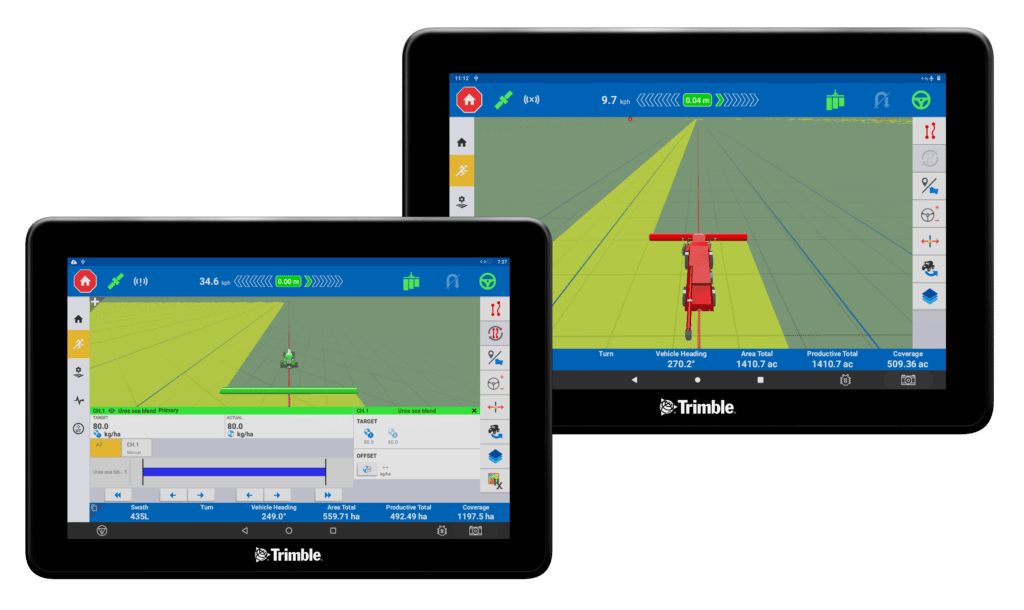

This approach has significantly increased their yield and allowed Pye Group to optimise fertiliser use and reduce waste. The precision approach to fertilising has had numerous benefits for the Pye Group, including cost savings on transportation, time, effort, labour, fuel, and equipment wear and tear. Additionally, having guidance on equipment has resulted in savings of up to 10% on overlap. This translates into close to $50,000 in savings per percent of overlap in nutrients.

Soil testing has also been used on their dairy farms to ensure that there is no nutrient overload at the front of the paddock where the gate is located. The cows always return to the dairy shed through the gate, transferring all the concentrated nutrients from the back of the paddock to the front in their manure and urine. With this information, The Pye Group has implemented exclusion zones in the first 10% of the paddock, as nutrients are not required there.

Tony Gould, Operations and Transport Manager, has been implementing PNM strategies with the help of Vantage NZ and Ravensdown and has invested a lot of time and effort into data capture and quality.

“You can’t argue with data and can make long-term, data-driven plans that relate to real information; it’s not estimated. People either overestimate or underestimate, but when you have the data, you can actually see what you have done and what the result has been. Unless you get soil testing done and use variable rate application, you just can’t make targeted decisions,” said Tony.

Precision agriculture has been a game-changer for the Pye Group, and they believe that it is a solution that can be implemented on any scale. You just need to start.

To find out how precision ag could help you to reduce costs and maximise profits, contact Vantage NZ on 0800 482 682 or vantage-nz.com.